First of all, what is the difference between a "sheave" and a "pulley"? Check out this description on Wikipedia. In short, it comes down to minor details and the words are often used interchangeably.

Sheaves and Belts

Sheaves are a common means of transmitting power from an electric motor or gas engine to the drive member. Sheaves are available in many diameters which allow a screw conveyor (also known as an auger), to be run at many different RPM's.

"B" section belts carry the load from the motor sheaves to the drive. The number of belts that are required to transmit the load depends on the pitch diameter of the driver (or motor pulley) and the type of belts used.

Two types of "B" section belts are used. The ratings between the two types differs greatly.

The gripnotch or cog belt features a notched section on the inside diameter of the belts. This allows the belt to coil around the smaller motor sheave instead of flexing the fibers of the belts which causes heat, creating a loss of horsepower. Also, the sides of the belt are cut, not molded which creates a raw gripping edge.

Because of high horsepower ratings per belt, gripnotch belts should not be used on aluminum or pressed steel pulleys.

The 5L belt is a FHP, or fractional horsepower belt. This belt is molded and relies mainly on tension of the belt to transmit the load. The 5L belt is usually recommended for small loads where single belt only applications are required. This is because 5L belts are not made in matched sets as are gripnotch belts, which would be required on multiple groove applications. In short, because 5L belts are not matched, exact length cannot be guaranteed from belt to belt making tensioning difficult.

Proper belt tension is important. Belts that are too loose will slip and wear prematurely. If tightened too tight, the belts will stretch or create an overhung load on the bearings of the reducer. Refer to the specifications provided by the manufacturer of your belt for instructions on how to properly tension the belt(s) on your equipment.

The site for hard to find mathematical formulas pertaining to grain handling and storage. Get grain handling and storage ideas here! Figure auger capacity, conveyor capacity and bucket elevator capacity.

Monday, March 16, 2015

Calculating Drive Belt Length and Belt Horsepower Capability For An Auger

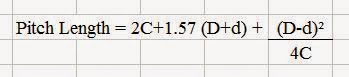

To determine the drive belt length required for an auger:

-Measure the center to center distance between the auger input shaft, and the motor shaft. (center to center distance the belt will have to span between the drive pulley and the driven pulley)

-Many auger manufacturers' catalogs often offer this measurement in the specifications section of their information.

(C) = Center to Center Distance

D = Drive Pulley Diameter

d = Driven Pulley Diameter

Note: The pitch length equation gives the required circumference for the belt at the midsection. The pitch diameter must be cross referenced in Chart X to determine the proper length for ordering belts.

Note: If the pitch length determined from the equation falls between the lengths given in chart No. X, choose the next larger belt.

-Measure the center to center distance between the auger input shaft, and the motor shaft. (center to center distance the belt will have to span between the drive pulley and the driven pulley)

-Many auger manufacturers' catalogs often offer this measurement in the specifications section of their information.

(C) = Center to Center Distance

D = Drive Pulley Diameter

d = Driven Pulley Diameter

Note: The pitch length equation gives the required circumference for the belt at the midsection. The pitch diameter must be cross referenced in Chart X to determine the proper length for ordering belts.

Note: If the pitch length determined from the equation falls between the lengths given in chart No. X, choose the next larger belt.

Note: Table XI shows how many horsepower a belt can handle based on pulley size. As the chart shows, belt wrap determines, to a great extent, the horsepower carrying capability of each belt.

Subscribe to:

Comments (Atom)